Pratt Institute Brooklyn Fashion + Design Accelerator

Ms. Bob Bland weaves together Manhattan expertise and Brooklyn energy

NEW YORK—A simple T-shirt can pass through 30 pairs of hands earlier it makes it to the consumer, and every single article of article of clothing nosotros wear is made by hand.

"People don't understand that, because when we remember of manufacturing we have this image of a Ford factory line. They don't understand how little of fashion is actually automated," said Bob Banal, founder and CEO of Manufacture New York, a tiny incubator in Midtown that has seen shut to 400 designers use the infinite to make their starts in the past twelvemonth.

The urban center has been the centre of fashion in the United States since the early 20th century, but rising rents and the alluring low costs of outsourcing are increasingly chipping away at Midtown Manhattan'south Garment District, with its 7.vii meg square feet of infinite in buildings from 34th to 42nd streets and Fifth to Ninth avenues.

In that location are efforts to preserve the Garment District as information technology stands, simply Bland is thinking bigger. Her goal is a sustainable solution that will let the industry abound through future generations and reverse the outsourcing tendency. To do that, Banal and others are capitalizing on the growing creative energy and resurgence of manufacturing in Brooklyn.

Sustainability

An article of article of clothing oft travels three or 4 continents before the terminal sale, and there are ethical and waste product-reducing choices that tin be made at so many points in between, said Debera Johnson, executive manager of Pratt Institute's Brooklyn Fashion and Design Accelerator (BFDA).

Consumers are becoming more aware of some of these impacts, but designers can lead the way. Pratt is developing a 20,000-foursquare-pes space at the onetime Pfizer building in Brooklyn to aid companies start and abound in a sustainable way.

"Designers have a lot of say almost what the earth looks like," Johnson said. "We're surrounded by the civilisation of design."

With these more than ethical choices comes a higher price tag, and then advocates for local manufacturing are typically dual advocates for sustainability.

The tendency is growing, and new designers keep to button it forward. Fiona Dieffenbacher, BFA manager in the Fashion Design department at Parsons, said her students are overwhelmingly interested in furthering the movement.

"The cost of fast mode—it's human uppercase at the end of the day," Dieffenbacher said. "The next generation has to modify that. They're the ones that can practise information technology."

Beyond ethics and environment, local manufacturing is too an issue of innovation.

"Local manufacturing is disquisitional," said Andrew Ward, adjunct professor at the Fashion Institute of Technology and acting executive director of the Garment Industry Development Corporation. "Without it, you lot're not going to create any new brands. It's that of import."

New Brands

A decade ago, if you'd asked a graduating course of style pattern majors how many planned to offset a business concern, about would heighten their hands. Today, very few do, Dieffenbacher said.

"They're more aware of the challenges than earlier with the Internet and people telling their stories," Dieffenbacher said. Stories of success are just equally valuable as those of failure, and it's all immortalized through social media. When a contempo graduate pulled dorsum from launching a line and decided to hold off, Dieffenbacher said, all his peers were on that journey with him through Facebook, Twitter, Instagram.

In a way, the digital movement has also helped to counter the depletion of the Garment District. Resource like Maker'southward Row, the urban center'due south Economical Development Corporation, and Council of Style Designers of America accept created databases connecting designers to every manufacturing resources they could demand, bolstering businesses.

Starting designers are met with a avalanche of business risks and challenges so many opt to intern and work for other companies for a few years before diving in, Dieffenbacher said. It'southward just the reality of the industry.

"The greenbacks menstruum in the fashion business organization is so, so tight," Dieffenbacher said.

Even a very small line is cost and time consuming. At about a few hundred dollars per sample, information technology easily totals tens of thousands earlier a new designer makes his or her first auction.

Private disinterestedness is sought later because fashion startups can't get loans unless the company has been open for 2 years, but venture capitalists and angel investors aren't available to them because they are virtually exclusively interested in tech companies.

The result is that many designers without financial support can't afford to stay, Bland said. Years ago she watched so many of her talented peers leave the city, equally anywhere was cheaper than New York. She kept holding out and waiting for someone—the city, or some nonprofit—to step in and create a resources to help designers launch in the city, simply it never happened.

"I realized if no one else is going to step in, I've got to do it," said Bland. Since and so her two,000-square-human foot hybrid incubator-factory in Manhattan has been the workspace of 300–400 designers who use information technology for blueprint making, sewing, product development, or fifty-fifty as a mailing address.

Bridging Midtown to Brooklyn

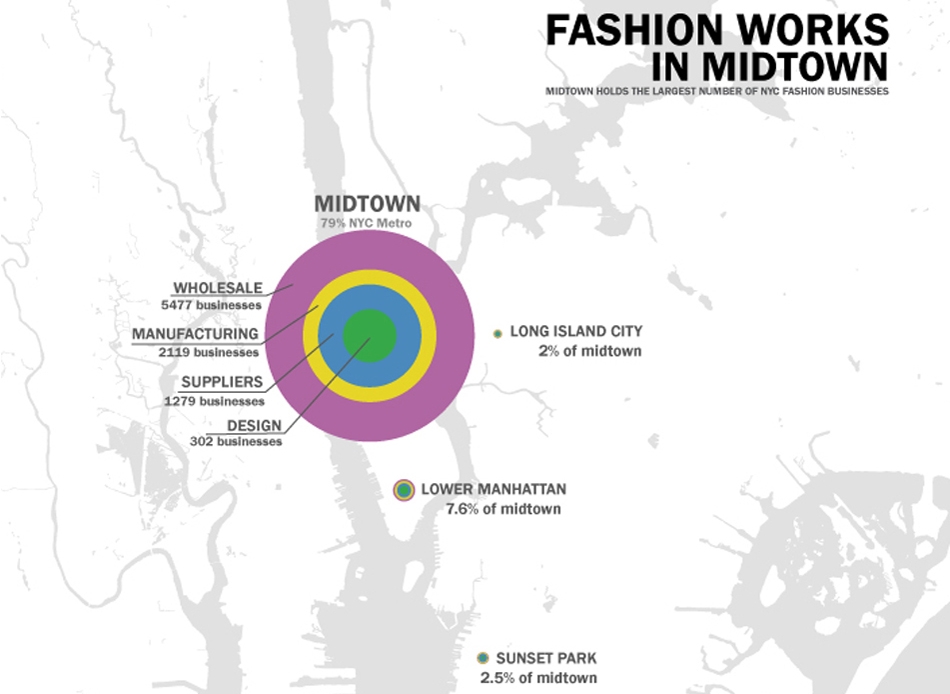

The centre and soul of the mode industry resides in just a few blocks across Midtown Manhattan. The majority of apparel manufacturers and vendors are based in the Garment District, sales are made at that place, and the energy during fashion weeks is unparalleled.

Equally with whatever other industry, proximity matters. A contempo MIT study found that 77 percent of all trips made by fashion designers are within the confines of the Garment Commune.

Sometimes a manufacturer will be pushed out to Long Isle City or Brooklyn, but their customers don't always follow.

Banal aims to change that with a vertically integrating hub that volition allow companies to scale up to high book production if needed.

A 160,000-square-foot floor space at Liberty View Industrial Plaza is currently in development. It spans an entire cake in Sunset Park, Brooklyn, next to the vibrant maker-customs of entrepreneurs who share six million square feet of space in Industry City.

Pratt's BFDA is making a similar motion, with its accelerator set to open up in the fall in Brooklyn. In 2002, Johnson founded the Pratt Design Incubator, which later evolved into a graduate section centre, and it showed her how necessary it was to provide resources to the general community of designers.

The Accelerator functions more than like a side by side step to the incubator.

"Short run apparel product is critical to companies that are scaling," Johnson said. Making one sample yourself is manageable, and ordering 500 equally a big visitor is successful, Johnson said, but getting from one cease to the other is very difficult. Thus all of the equipment—knitting machines, digital fabrication machines, and then on—will exist available to anyone needing to make pocket-sized-run orders of 15–20, a crucial footstep for small companies to make sales.

Existence sustainable ways in an economic sense as well, Banal adds.

"This was always a 20-yr project for me, to provide new jobs not merely for my generation merely our children'south generation," Banal said.

When Bland decided to showtime Manufacture New York, she spent the first year only on customs edifice. Jobs in the trade are high-skill and high-wage, and when the Brooklyn location opens, Bland hopes to bring in the local customs.

The plan is to have every aspect of the manufacturing process possible in the space, from textile manufacturers to pattern making, to even a research and development tech annex. It will include workforce evolution training, tours for the public, and an estimated 280 jobs.

The hub of interrelated companies will create the opportunity for a Garment Commune to grow in Brooklyn in a way that it cannot in Manhattan, and start to remove the concrete need to be located in Manhattan, where rents run up to $40 per square human foot for industrial infinite.

"This is an oasis," Bland said. "Companies tin sign 20-twelvemonth leases with united states of america, if they desire to."

Garment District in Quotes

The interest [in sustainability] is nowadays in all of our students. In the terminal three to v years it has really grown, and it's non a trend that'southward going abroad.—Fiona Dieffenbacher, BFA Managing director of Fashion Design at Parsons

[Brooklyn] is the artistic heart of the universe. … Personally, seeing immature people who are making changes in the world—I want to run across them flourish. I want to see them succeed.—Debera Johnson, executive director, Brooklyn Fashion+Pattern Accelerator

In the Garment District yous tin can witness the entire fashion wheel: new brands coming in and growing, growing to the top earlier they refuse.—Andrew Ward, FIT adjunct professor and interim executive manager, Garment Manufacture Development Corporation

Tech Annex

Manufacture New York's Brooklyn manufacturing center at the Freedom View Industrial Plaza will include a tech annex and research and evolution center that could fit up to 25 fashion-tech startups for everything from habiliment tech, to new textiles, to new hardware for manufacturing.

"three-D printing is just i part of it, rapid prototyping is just one part of it. A lot of industries really emphasize that, but we're looking at everything from biofabrics—textiles rendered from algae—to embedded tech, like magnetic and copper wires embedded into material to basically brand your clothes into batteries," Bob Bland, founder and CEO of Manufacture New York, said. "It's really limitless what we'll be able to do with the tech addendum and R&D middle."

Tech companies will likewise benefit from working close to designers, and vice versa.

"It'll allow aesthetics to come into play," Bland said. "Sometimes … information technology doesn't look good, and that's because you lot didn't accept designers sitting with developers, technologists. So it'southward very of import for technology companies to have the ability to examination with designers and interact with designers."

Fashion Industry by the Numbers*

At ane time, 95 pct of the wear sold in the United States was manufactured in New York City's Garment District, and that FIGURE has dwindled downwardly to iii percent. As consumers become increasingly interested in sustainable options, interested groups and the urban center are looking for ways to preserve and aggrandize the district, possibly into the outer boroughs.

NUMBERS:

- $98 billion: Economic bear upon on NYC in 2012

- 900: Mode companies headquartered in New York

- 80%: Business organization-related trips made by style designers within the Garment District

- vii.7 one thousand thousand foursquare feet: Size of the Garment Commune, totaling less than one square mile, in Midtown Manhattan

- vi%: Of the metropolis'south workforce is in the way industry (180,000)

- 500+: Almanac fashion shows during New York'southward semiannual fashion weeks

*Source: NYCEDC, MIT, Municipal Arts Society's "The Garment Commune New York City 2011 Report"

(The Garment Commune New York City 2011 Report/Municipal Arts Society)

0 Response to "Pratt Institute Brooklyn Fashion + Design Accelerator"

Post a Comment